Thermal management for Silicon Validation

- The demand for high-performance microprocessors has resulted an escalation of power dissipation and heat flux at the silicon level. At the same time, the desire for small form- factor chassis , new car industry specification demand for very low and very high Silicon operating temperatures bring the thermal solution challenge to new levels. Silicon validation platform are built to validate Processors, Chipset and PCB's to ensure quality and reliable products in temperature range of -40c to 150c .These validation phase is crustal step in releasing the product to market. Recently it become challenging to design a forcing thermal solution for high speed processors, Networks components, Graphic cards, Memory and voltage regulators etc. High Si temperature cause various problems such as increased leakage, accelerating failure mechanisms and inducing timing failures. Thermal-related effects are considered as a major roadblock in the design on next generation microprocessors. The tests have to be conducted to get necessary data which may show a big difference from the data sheet provided by the vendor due to different boundary conditions.

There are few technology concepts used in thermal solution for Electronic validation need :

- Liquid or Air cooling is commonly used to cool CPUs as well as other computer components. It usually consists of a CPU liquid block, a liquid pump, and a heat exchanger (mostly a radiator and fan). Advantage is low cost.

- Liquid cooling allows quieter operation (potentially fan less), or improved processor speeds. ( high cost as u need to provide cooled liquid)

- Phase change cooling technology is suitable when very low temp is desired (-40c) efficiency is much higher - and does not need cooling liquid to remove the heat. Thermal Electrical Cooler (TEC) can not always remove the amount of heat capacity needed at such low low temperature of (minus forty) -40c\ and it's efficiency is very low (~30%) disadvantage of phase change technology is higher cost for initial system purchase but it is very energy efficient - for long usage run one may need to calculate the energy cost vs. system cost and make the right decision what technology to be used

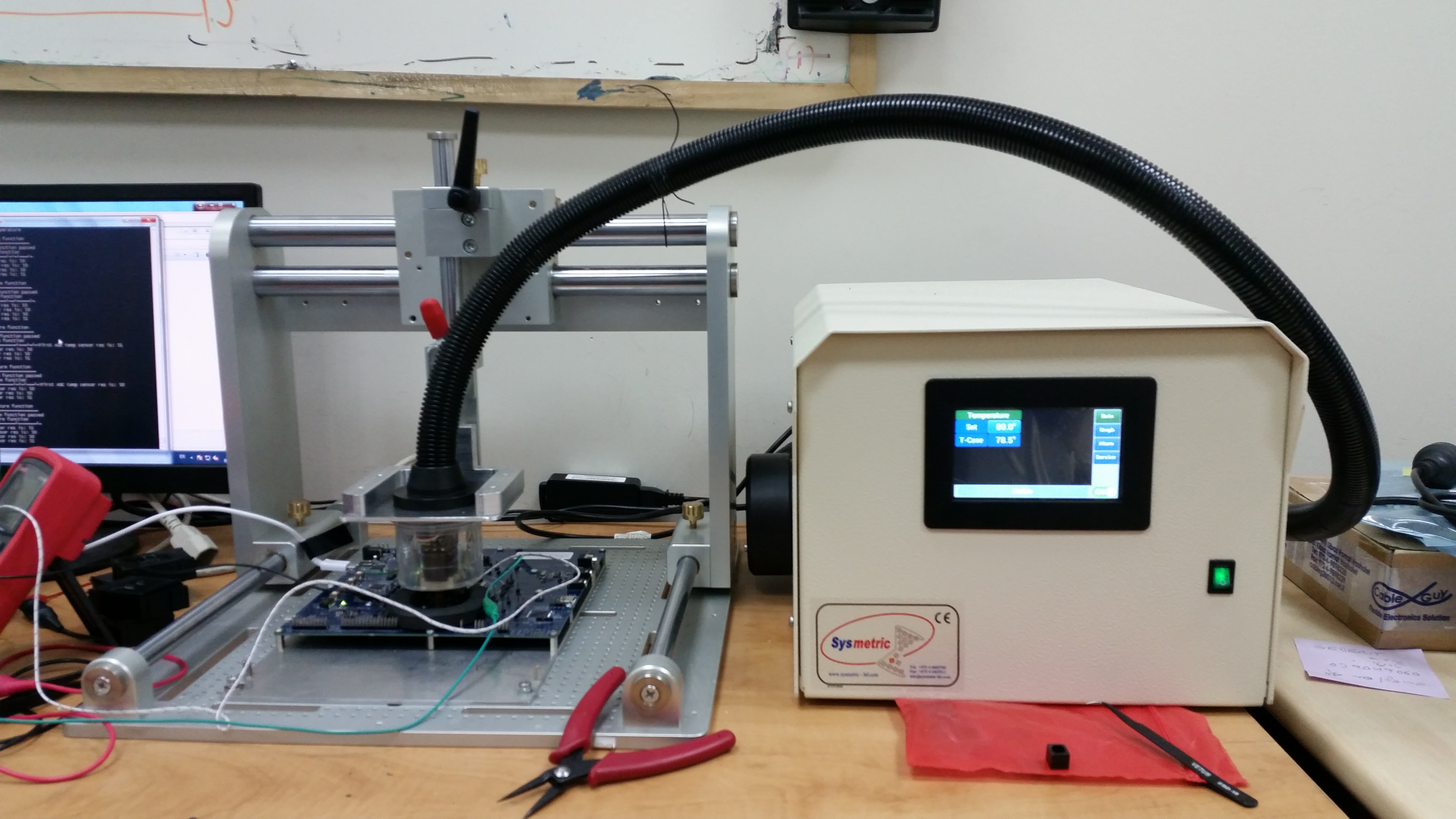

Phase change cooling system for temp range -40c up to 150 c (160 watt @ 0c)

Pcb Desktop Chamber Temp range -30c - 110c